Johnny W Morlan Woodworking Artist 의 모든 작품

Custom Made Commissioned Wooden Pieces • 25 작품

모두보기

"Excellence is the result of caring more than others think is wise,

risking more than others think is[...]

"Excellence is the result of caring more than others think is wise,

risking more than others think is safe, dreaming more than others think is practical and expecting more than others think is possible." Mac Anderson

Custom Made Order Information

Custom & special made orders are scheduled and with my current demand for orders, it will be approximately 4 - 6 weeks {see exception below}, from the date the down payment {retainer} on the order is made, before I will be able to start making the piece/pieces.

I leave room in my schedule for small orders, {kind of like a doctors office} that I call human nature spur of the moment orders that are needed within 2 weeks because of wanting them for a special occasion such as a birthday, anniversary etcetera. These exceptions are pieces like pens, letter openers, desk sets, desktop business card holders, small plaques etcetera.

Some of the custom made orders I have scheduled to make in the near future are, a Figured Walnut Wood Coin Presentation Box for a set of 5 - 1878 U. S. Morgan Silver Dollars, a Walnut Bible Box for a 250 year old heirloom bible, 2 - 10 Cherry Wood Multiple Reception Area Business Card Holders for a business advisory company in Australia, 1 - 3 foot long and 1 - 4 foot long Oak Wood 4 door cabinets with pull out shelves for a doctors business office.

Custom & special made orders will not be scheduled until the down payment {retainer} has been made.

For choosing font styles for engraving, I can e-mail a Microsoft Word document featuring them.

Custom Made Order Payment Information

The way I work custom made or commissioned orders are, I receive 1/2 the total cost as a deposit {retainer} up front and receive the remaining 1/2 when you receive it. Before I ship, I take photos of the piece/pieces with my digital camera and send an e-mail with JPEG images attached. Shortly afterward it will be shipped and you will receive a shipping confirmation number.

For the deposit {retainer} and down payment, I accept personal/company checks, cashiers checks, money orders and payments through PayPal.

If PayPal is used for the deposit {retainer}, payment is expected to be sent within 24 hours of accepting the quote. I will send a receipt by e-mail.

The remaining 1/2 is expected within 48 hours after receiving it. I will send a receipt by e-mail.

If personal/company checks, cashiers checks or money orders are used for the deposit {retainer} payment is expected to be received within 7 days of accepting the quote. Once check or money order is received, a receipt will be sent your choice, by either e-mail or mail.

The remaining 1/2 is expected within 7 days after receiving it. Once check or money order is received, a receipt will be sent your choice by either e-mail or mail.

Custom Made Order Refund Policy

If after receiving your order, you do not like it, I will refund your total amount and the piece or pieces are mine to do with as I wish! I will pay the shipping back to me by UPS ground.

risking more than others think is safe, dreaming more than others think is practical and expecting more than others think is possible." Mac Anderson

Custom Made Order Information

Custom & special made orders are scheduled and with my current demand for orders, it will be approximately 4 - 6 weeks {see exception below}, from the date the down payment {retainer} on the order is made, before I will be able to start making the piece/pieces.

I leave room in my schedule for small orders, {kind of like a doctors office} that I call human nature spur of the moment orders that are needed within 2 weeks because of wanting them for a special occasion such as a birthday, anniversary etcetera. These exceptions are pieces like pens, letter openers, desk sets, desktop business card holders, small plaques etcetera.

Some of the custom made orders I have scheduled to make in the near future are, a Figured Walnut Wood Coin Presentation Box for a set of 5 - 1878 U. S. Morgan Silver Dollars, a Walnut Bible Box for a 250 year old heirloom bible, 2 - 10 Cherry Wood Multiple Reception Area Business Card Holders for a business advisory company in Australia, 1 - 3 foot long and 1 - 4 foot long Oak Wood 4 door cabinets with pull out shelves for a doctors business office.

Custom & special made orders will not be scheduled until the down payment {retainer} has been made.

For choosing font styles for engraving, I can e-mail a Microsoft Word document featuring them.

Custom Made Order Payment Information

The way I work custom made or commissioned orders are, I receive 1/2 the total cost as a deposit {retainer} up front and receive the remaining 1/2 when you receive it. Before I ship, I take photos of the piece/pieces with my digital camera and send an e-mail with JPEG images attached. Shortly afterward it will be shipped and you will receive a shipping confirmation number.

For the deposit {retainer} and down payment, I accept personal/company checks, cashiers checks, money orders and payments through PayPal.

If PayPal is used for the deposit {retainer}, payment is expected to be sent within 24 hours of accepting the quote. I will send a receipt by e-mail.

The remaining 1/2 is expected within 48 hours after receiving it. I will send a receipt by e-mail.

If personal/company checks, cashiers checks or money orders are used for the deposit {retainer} payment is expected to be received within 7 days of accepting the quote. Once check or money order is received, a receipt will be sent your choice, by either e-mail or mail.

The remaining 1/2 is expected within 7 days after receiving it. Once check or money order is received, a receipt will be sent your choice by either e-mail or mail.

Custom Made Order Refund Policy

If after receiving your order, you do not like it, I will refund your total amount and the piece or pieces are mine to do with as I wish! I will pay the shipping back to me by UPS ground.

Wooden Boxes & Showcases • 11 작품

모두보기

Overall Wood Box Construction Technique

Boxes can be any creations that have three or more sides and[...]

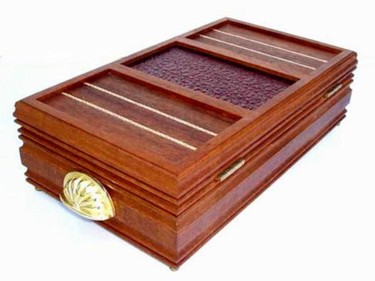

Overall Wood Box Construction Technique

Boxes can be any creations that have three or more sides and are meant to be displayed either laying flat on a 180 degree surface or standing or hanging in a 90 degree horizontal upright position.

Johnny's wood box creations can take 175-250 separate steps or procedures from start to completion. His more intricate jewelry box creations that have partitioned trays, a musical movement, are lined with velvet, have partitioned lids with stained glass and mirror panels take over 250 separate steps or procedures to complete.

Johnny selects the wood for each and every one of his creations, based on its grain, figure patterns {reading the wood} color, and how much it moves in service {expands and contracts} with temperature & humidity changes. Lumber is checked with a moisture meter, only lumber with moisture content of 6%-12% is used. Lumber in this range is extremely stable.

Each box creation and all its wood components come from either one individual piece of wood or from woods in the same movement category thus allowing the whole unit to move the same amount. The sides of the boxes, trays and Spanish Cedar linings {cigar humidors} are cut in an order which allows the figure and grain patterns of the wood to be continuous wrapping around the perimeter of the box.

The corner joints are cut at a mitered angle appropriate to the number of sides the box creation has. 3 sided - 60 degrees, 4 sided - 45 degrees, 5 sided - 36 degrees, 6 sided - 30 degrees, 7 sided - 25.71 degrees {26 is close enough}, 8 sided - 22.5 degrees, 9 sided - 20 degrees, 10 sided - 18 degrees, 11 sided - 16.36 degrees {16 is close enough}, 12 sided - 15 degrees, 15 sided - 12 degrees, 16 sided - 11.25 degrees {11 is close enough}.

All corner joints have hidden biscuits. The shape of the biscuits differs a little from those that can be bought already made. The biscuits are cut utilizing a bandsaw from the same wood the box is made and so the grain runs across the biscuit instead of vertically {up and down} the long way. This way the grain is running the same way as the box sides and is the same as gluing two pieces of wood face to face. This technique produces an extremely strong joint!

Wood Jewelry Box Construction Technique Featuring Stained Glass & Mirror Panels

Any box creations with back to back wood and stained glass, wood and mirror glass or stained glass and mirror glass panels are done utilizing a technique, which separates the two panels with a soft cushiony type material that under normal use, absorbs the impact of any sudden jar and will keep the glass from breaking.

Wood Music Box Construction Technique

With music box creations, if the wood is left unfinished there are woods such as Mahogany, Alder and Spruce that will produce a richer sound {tone} than others. When left unfinished, harder woods will not absorb the repercussions of the notes as much as softer woods, therefore producing a fuller, louder, richer and crisper sound {tone}. When the wood is finish coated with lacquer, shellac, polyurethane, etcetera, it will cause the sound to bounce off the coating instead of the wood, so even softer woods will have a richer sound {tone}. A softer finish coating such as Tung Oil will produce a mellower sound than lacquers and shellacs. To make the sound repercussion even richer, Johnny surrounds the perimeter of the musical movement with wood, leaving the top open, so the sound is bounced off the perimeter sides {funneled} to the top and then out.

Wood Cigar Humidor Construction Technique

His cigar humidor lids, have to be slightly pressed closed the last 1/2" or so creating the swoosh effect. This indicates and insures the humidor has an airtight seal thus making the inside a fully self contained separate environment. Without the swoosh effect, all it would be is an ordinary box. This is accomplished by cutting the linings 1/2" taller to allow them to stick up inside the lid 1/2" when closed. The lid is also recessed 1/2" to allow the linings and the lid to fit together tightly.

If a cigar humidor is opened and closed {used} frequently, there will be no problem with mold. Because Johnny's humidors are a fully self contained separate environment, there is no air exchange what so ever between the outside and the inside environments. If not opened and closed {used} very much, they should be opened every two weeks or so for a couple of minutes.

Spanish Cedar, the traditional lining for humidors, is in the minute wood movement category, it does not expand and contract as much as the majority of woods do. Johnny either leaves the Spanish Cedar linings floating or he slots the linings and uses stainless steel screws to affix them so as to allow the two woods to slide along one another resulting in no damage to the humidor when it expands and contracts. To leave floating, Johnny cuts the corner joints at 45 degrees making them fit somewhat snugly. Humidors are kept at 70% humidity. Most houses and his shop are kept at 50% or less humidity. At 70% humidity, the Spanish Cedar linings will then expand a little more, thus making the linings fit even more snug.

Spanish Cedar gives off a fragrant scent, because of the oil inside which can also ooze out {sweating} of the surface and appear as a sticky resinous type substance. This is not good if it gets on the cigars. Johnny checks and makes sure that the Spanish Cedar that is used for linings that go into each of his humidors do not have the oils oozing out {sweating}.

Johnny has lined, custom made humidors with Aromatic Cedar, because the client did not want their cigars smelling like Spanish Cedar. He has also lined the entire inside of a humidor with velvet, because the client wanted their cigars to smell natural.

Whether Aromatic or Spanish Cedar wood linings are used, Johnny leaves them unfinished, because any type of coating would seal the wood thus stopping it from giving off the fragrance. Also, the finer the sandpaper used to sand the linings, the less fragrance either wood will give off.

Johnny's Technique For Better Air Circulation

From Johnny's own personal experience, if cigars are stacked more than 3 tiers high, the cigars on the bottom tier do not get as much air as the cigars on the upper tiers.

His technique does circulate the air a lot better. He makes a second bottom {false bottom}, that he drills numerous holes into. It sits on top of 3/8" slats, two that are placed on opposites sides and depending on how long the humidor is 1 - 3 in the middle. The slats are all sitting on the true bottom of the humidor thus making an airspace. Then he leaves 1/4" - 1/2" or more at both ends of the cigars. This allows air to circulate all around the stack. He uses this technique on most of his custom made to order cigar humidors.

Dear Mr. Morlan, The humidor you made for me has outstanding craftsmanship and character. I am a stickler about cigars. Mine have always been stacked 6 high in the box. I knew and could tell that the bottom 2 rows were not getting that much air so I have always rotated my cigars. Your technique for air circulation works great! Larry H - Bethesda, Maryland

Wood Finish Technique

There are numerous techniques and finishes for finishing wood, a true wood artist develops their own techniques and finish to bring out the beauty of their works.

Johnny's technique for finishing wood {small pieces that are not handled or used a lot} is not to fill the pores, thus showcasing the intricacy of his designs and the natural character, distinction and depth of the wood making each piece one of a kind, just like your own fingerprint does for you.

Wood is such a beautiful medium to work with he does not wish to hide its natural beauty by utilizing numerous coats of lacquer, shellac, polyurethane, and etcetera. He handcoats and rubs in the first coat, then adds two more handcoated topcoats using a clear marine grade polyurethane spar varnish that is impervious to most liquids including body oils and some mild acids. It also has ultraviolet inhibitors in it to repel the suns UV rays. Johnny adds a couple of other ingredients to make it easier to apply and be worked into the wood with a cloth thus allowing the finish to penetrate the wood but not thick enough to take away the three dimensional look of the surface or giving an effect of looking like a piece of plastic.

Boxes can be any creations that have three or more sides and are meant to be displayed either laying flat on a 180 degree surface or standing or hanging in a 90 degree horizontal upright position.

Johnny's wood box creations can take 175-250 separate steps or procedures from start to completion. His more intricate jewelry box creations that have partitioned trays, a musical movement, are lined with velvet, have partitioned lids with stained glass and mirror panels take over 250 separate steps or procedures to complete.

Johnny selects the wood for each and every one of his creations, based on its grain, figure patterns {reading the wood} color, and how much it moves in service {expands and contracts} with temperature & humidity changes. Lumber is checked with a moisture meter, only lumber with moisture content of 6%-12% is used. Lumber in this range is extremely stable.

Each box creation and all its wood components come from either one individual piece of wood or from woods in the same movement category thus allowing the whole unit to move the same amount. The sides of the boxes, trays and Spanish Cedar linings {cigar humidors} are cut in an order which allows the figure and grain patterns of the wood to be continuous wrapping around the perimeter of the box.

The corner joints are cut at a mitered angle appropriate to the number of sides the box creation has. 3 sided - 60 degrees, 4 sided - 45 degrees, 5 sided - 36 degrees, 6 sided - 30 degrees, 7 sided - 25.71 degrees {26 is close enough}, 8 sided - 22.5 degrees, 9 sided - 20 degrees, 10 sided - 18 degrees, 11 sided - 16.36 degrees {16 is close enough}, 12 sided - 15 degrees, 15 sided - 12 degrees, 16 sided - 11.25 degrees {11 is close enough}.

All corner joints have hidden biscuits. The shape of the biscuits differs a little from those that can be bought already made. The biscuits are cut utilizing a bandsaw from the same wood the box is made and so the grain runs across the biscuit instead of vertically {up and down} the long way. This way the grain is running the same way as the box sides and is the same as gluing two pieces of wood face to face. This technique produces an extremely strong joint!

Wood Jewelry Box Construction Technique Featuring Stained Glass & Mirror Panels

Any box creations with back to back wood and stained glass, wood and mirror glass or stained glass and mirror glass panels are done utilizing a technique, which separates the two panels with a soft cushiony type material that under normal use, absorbs the impact of any sudden jar and will keep the glass from breaking.

Wood Music Box Construction Technique

With music box creations, if the wood is left unfinished there are woods such as Mahogany, Alder and Spruce that will produce a richer sound {tone} than others. When left unfinished, harder woods will not absorb the repercussions of the notes as much as softer woods, therefore producing a fuller, louder, richer and crisper sound {tone}. When the wood is finish coated with lacquer, shellac, polyurethane, etcetera, it will cause the sound to bounce off the coating instead of the wood, so even softer woods will have a richer sound {tone}. A softer finish coating such as Tung Oil will produce a mellower sound than lacquers and shellacs. To make the sound repercussion even richer, Johnny surrounds the perimeter of the musical movement with wood, leaving the top open, so the sound is bounced off the perimeter sides {funneled} to the top and then out.

Wood Cigar Humidor Construction Technique

His cigar humidor lids, have to be slightly pressed closed the last 1/2" or so creating the swoosh effect. This indicates and insures the humidor has an airtight seal thus making the inside a fully self contained separate environment. Without the swoosh effect, all it would be is an ordinary box. This is accomplished by cutting the linings 1/2" taller to allow them to stick up inside the lid 1/2" when closed. The lid is also recessed 1/2" to allow the linings and the lid to fit together tightly.

If a cigar humidor is opened and closed {used} frequently, there will be no problem with mold. Because Johnny's humidors are a fully self contained separate environment, there is no air exchange what so ever between the outside and the inside environments. If not opened and closed {used} very much, they should be opened every two weeks or so for a couple of minutes.

Spanish Cedar, the traditional lining for humidors, is in the minute wood movement category, it does not expand and contract as much as the majority of woods do. Johnny either leaves the Spanish Cedar linings floating or he slots the linings and uses stainless steel screws to affix them so as to allow the two woods to slide along one another resulting in no damage to the humidor when it expands and contracts. To leave floating, Johnny cuts the corner joints at 45 degrees making them fit somewhat snugly. Humidors are kept at 70% humidity. Most houses and his shop are kept at 50% or less humidity. At 70% humidity, the Spanish Cedar linings will then expand a little more, thus making the linings fit even more snug.

Spanish Cedar gives off a fragrant scent, because of the oil inside which can also ooze out {sweating} of the surface and appear as a sticky resinous type substance. This is not good if it gets on the cigars. Johnny checks and makes sure that the Spanish Cedar that is used for linings that go into each of his humidors do not have the oils oozing out {sweating}.

Johnny has lined, custom made humidors with Aromatic Cedar, because the client did not want their cigars smelling like Spanish Cedar. He has also lined the entire inside of a humidor with velvet, because the client wanted their cigars to smell natural.

Whether Aromatic or Spanish Cedar wood linings are used, Johnny leaves them unfinished, because any type of coating would seal the wood thus stopping it from giving off the fragrance. Also, the finer the sandpaper used to sand the linings, the less fragrance either wood will give off.

Johnny's Technique For Better Air Circulation

From Johnny's own personal experience, if cigars are stacked more than 3 tiers high, the cigars on the bottom tier do not get as much air as the cigars on the upper tiers.

His technique does circulate the air a lot better. He makes a second bottom {false bottom}, that he drills numerous holes into. It sits on top of 3/8" slats, two that are placed on opposites sides and depending on how long the humidor is 1 - 3 in the middle. The slats are all sitting on the true bottom of the humidor thus making an airspace. Then he leaves 1/4" - 1/2" or more at both ends of the cigars. This allows air to circulate all around the stack. He uses this technique on most of his custom made to order cigar humidors.

Dear Mr. Morlan, The humidor you made for me has outstanding craftsmanship and character. I am a stickler about cigars. Mine have always been stacked 6 high in the box. I knew and could tell that the bottom 2 rows were not getting that much air so I have always rotated my cigars. Your technique for air circulation works great! Larry H - Bethesda, Maryland

Wood Finish Technique

There are numerous techniques and finishes for finishing wood, a true wood artist develops their own techniques and finish to bring out the beauty of their works.

Johnny's technique for finishing wood {small pieces that are not handled or used a lot} is not to fill the pores, thus showcasing the intricacy of his designs and the natural character, distinction and depth of the wood making each piece one of a kind, just like your own fingerprint does for you.

Wood is such a beautiful medium to work with he does not wish to hide its natural beauty by utilizing numerous coats of lacquer, shellac, polyurethane, and etcetera. He handcoats and rubs in the first coat, then adds two more handcoated topcoats using a clear marine grade polyurethane spar varnish that is impervious to most liquids including body oils and some mild acids. It also has ultraviolet inhibitors in it to repel the suns UV rays. Johnny adds a couple of other ingredients to make it easier to apply and be worked into the wood with a cloth thus allowing the finish to penetrate the wood but not thick enough to take away the three dimensional look of the surface or giving an effect of looking like a piece of plastic.

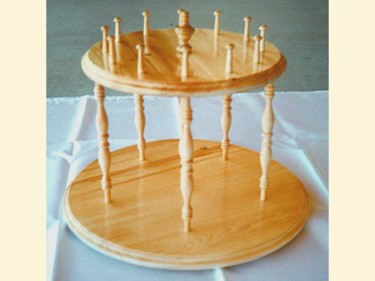

Wooden Special Pieces & Desk Accessories • 19 작품

모두보기Wooden Letter Openers • 10 작품

모두보기판매된 작품 • 26 작품

연락처 Johnny W Morlan Woodworking Artist

Johnny W Morlan Woodworking Artist에게 개인 메시지 보내기